Elastic Rail Clip

Elastic rail clip offered by AGICO is very important components that are heavily used in laying of railway tracks. We manufacture these rail clips using finest quality raw material ensuring enhanced sturdiness and long durability. Moreover, our rail clips are made of forged spring steel which is thought the best raw material. Therefore, elastic rail clips we manufactured saved a large amount of maintenance cost.

As a professional manufacturer and supplier of railroad fasteners, with rail clip as our most popular products, we are capable of producing extensive range of elastic rail clips with optimum quality. Designed with high precision, our rail clips are imparted with high tensile strength and corrosion resistance. With more than 20 years’ rich experience, our monthly production capacity can be up to 5,000.000 pieces which could help shorter delivery time. Strict dimensional control and the use of high quality spring steel but best price is our one competition. Another competition is that we can produce various kinds or elastic rail clips like E-type (E1609, E1809, E1817, E2007, E2009, E2055, etc), SKL tension clamps (SKL1, SKL3, SKL12, SKL14, SKL75, etc), PR series, N clips, gauge lock clip, Deenik clip as well as other standard and non-standard clips(e.g. Vossloh) can be customized by drawing or samples.

Main Series of Elastic Rail Clip

| Series | Type | Hardness | Material | Fatigue life | Surface | Standard |

|---|---|---|---|---|---|---|

|

E rail clip |

E1,E2,E3 |

44-48HRC |

60Si2MnA: C:0.56-0.64, Mn:0.60-0.90, Si:1.60-2.00, Cr:≤0.35, P:≤0.03, S:≤0.03 60Si2CrA: C:0.56-0.64, Mn:0.40-0.70, Si:1.40-1.80,Cr:0.70-1.00 P:≤0.03, S:≤0.03 55Si2Mn: C:0.52-0.60, Mn:0.60-0.90, Si:1.50-2.00,Cr:≤0.35 P:≤0.03, S:≤0.03 38Si7: C:0.35-0.42, Mn:0.50-0.80, Si:1.50-1.80, P:≤0.03, S:≤0.03 |

For Dia.18 is 3 million cycles without breaking. For Dia.20 is 5 million cycles without breaking. |

plain (oiled), Oxide black, color painting or according to customer requirement. |

DIN17221, BS970, GB/T1222 |

| E1609 | ||||||

| E1809 | ||||||

| E1817 | ||||||

| E2001 | ||||||

| E2006 | ||||||

| E2009 | ||||||

| E2055 | ||||||

| E2056 | ||||||

|

Vossloh clip& Forged rail clip |

SKL1 |

42-47HRC

|

||||

|

PR rail clip |

PR309 |

44-48HRC |

||||

| PR401 | ||||||

| PR601 | ||||||

| PR85 | ||||||

| We can also produce customized rail clips according to your drawings or samples! | ||||||

Main Elastic Rail Clip Products

| Model | Diameter | Weight | Material |

|---|---|---|---|

| Type III | Ø18 | 0.80kg/pc | 60Si2MnA |

| E1609 | Ø16 | 0.43 kg/pc | 60Si2MnA |

| E1809 | Ø20 | 0.61kg/pc | 60Si2MnA |

| E1813 | Ø18 | 0.62kg/pc | 60Si2MnA |

| E2001 | Ø20 | 0.80kg/pc | 60Si2MnA |

| E2007 | Ø20 | 0.80kg/pc | 60Si2MnA |

| E2009 | Ø20 | 0.80kg/pc | 60Si2MnA |

| E2039 | Ø20 | 0.80kg/pc | 60Si2MnA |

| E2055 | Ø20 | 0.80kg/pc | 60Si2MnA |

| E2056 | Ø20 | 0.80kg/pc | 60Si2MnA |

| E2063 | Ø20 | 0.80kg/pc | 60Si2MnA |

| PR85 Rail Clip | Ø13 | 0.25kg/pc | 60Si2MnA |

| PR309A | Ø19 | 0.85kg/pc | 60Si2MnA |

| PR401 | Ø20 | 0.97kg/pc | 60Si2MnA |

| PR415 | Ø20 | 0.95kg/pc | 60Si2MnA |

| PR601A | Ø20 | 1.03kg/pc | 38Si7 |

| SKL 1 | Ø13 | 0.48kg/pc | 60Si2CrA |

| SKL 3 | Ø13 | 0.48kg/pc | 60Si2CrA |

| SKL 12 | Ø13 | 0.53kg/pc | 38Si7 |

| SKL 14 | Ø13 | 0.53kg/pc | 60Si2MnA |

| Special Rail Clip | Ø13 | 0.48kg/pc | 60Si2MnA |

| Russia Rail Clip | Ø18 | 0.58kg/pc | 60Si2MnA |

| Deenik Clip | Ø25 | 0.49-0.68kg/pc | 60Si2MnA |

|

Single Anti- Theft |

Ø20 | 0.25kg/pc | 60Si2MnA |

Hot-sale Rail Clips

| Item | Image | Diameter | Weight | Export Destination |

|---|---|---|---|---|

|

E1809 Rail Clip |

|

Ø20 |

0.61kg/pc |

Southeast Asia |

|

E2055 Rail Clip |

|

Ø20 |

0.80kg/pc |

America |

|

PR601A Rail Elastic Clip |

|

Ø20 |

1.03kg/pc |

America, Taiwan |

|

Anti-vandal Rail Clip |

|

Ø20 |

0.25kg/pc |

Indonesia |

|

Rail Fast Clip |

|

Ø15 |

0.58kg/pc |

Singapore |

|

GL1419 Rail Clip |

|

Ø14 |

0.5kg/pc |

Argentina |

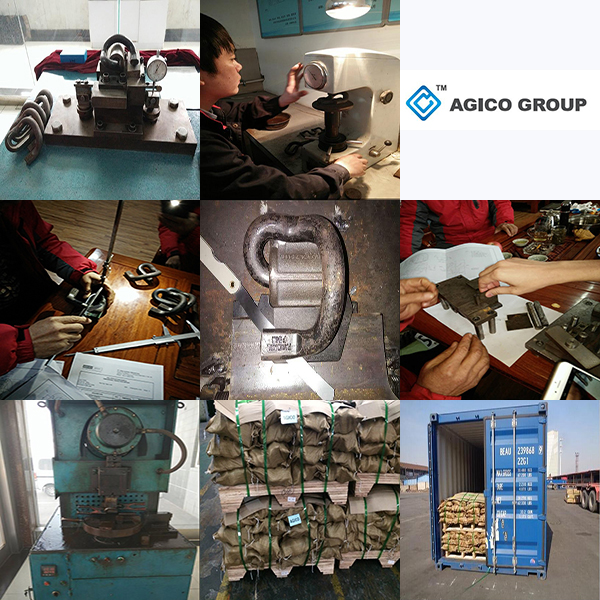

Rail Clip Production Process

Adhering to quality first, AGICO pay great attention to rail clip production process. With professional technic workers and strict quality monitoring, AGICO elastic rail clip processing procedures are as follows:

- Raw material: High quality spring steel from reliable and certified manufacturers for a long time.

- Shearing: Spring steel bar must be cut according to the required length.

- Heating: Forging temperature (950-1000 degrees Celsius), but over heating shall be avoided to check decarburization.

- Forming: Proper heating rods shall be transferred to the forging press.

- Hardening: Forged rail clips moved to the quench tank. Dimensional accuracy and quench hardness of rail clips are checked before tempering.

- Tempering: The rail clips are tempered at about 350 Celsius to achieve appropriate toughness in the spring.

- Inspection: Products are checked thoroughly as per China CRCC and customer required specification and design.

- Packing: Clips can be packed in woven bags or upon customer requirement

Rail Clip Inspection and Packing

Inspection Machines

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!