The Unknown Knowledge of Track Bolt for Beginners

Track bolt, a kind of machinery railway part, is composed of two parts of head and screw (cylinder with external thread) with a cylindrical threaded nut. The bolt is used for fastening and connecting with two-hole parts. Unscrewing the bolt, we can get two separated parts. So the bolt connection belongs to detachably connected.

According to the force connection, it can be divided into ordinary type and hinged type; according to the shape of the head, it can be divided into hex head type, round type, square head type, countersunk head type and so on. Of them, the hex head type of bolt is the most commonly applied in the local connection requirements.

Function of track bolt

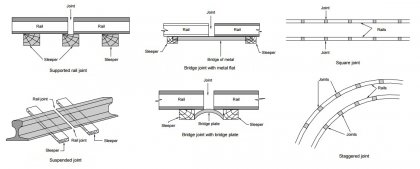

A track bolt is commonly used in railway construction as a mean of fastening the track it is applied to. In most cases, when a new rail is built, in order to secure a track or connect two rails, it must be tightened through the use of a track bolt that holds the track’s rail in right place. The track bolt itself is consisted of more than just a threaded bolt. It usually includes two or three-part of fasteners which are a threaded bolt, a nut and sometimes a lock washer. The washer can prevent the track bolt from shifting or getting loose through the intense vibrations caused by a passing train. Once the lock washer can engage the bolt, the bolt is then kept from slipping or twisting loose. This is the most common method for fastening a rail track for the rail fastening system.

Due to the needs of the fastening system, it has to be as strong as possible to prevent any possibility of shifting. As a result, most of the track bolts are made out of hardened steel. The steel is specially treated for preventing it from becoming easy to be rusty. Regardless whether the tracks are made out of concrete, wood, or any other material, a track bolt shall be met with the requirements of different designs of railways.

High strength track bolt

The key that trains can run smoothly on the track is that track bolt plays a great role due to its strength and reliability.

Connected by rail with the foundation or fishplate, the strength of bolts and their matched nuts directly affects the safety and reliability of the track. Bolts and nuts work under the influence of tensile stress. And the bolts often crack and then fracture because of fatigue. Nowadays with quick development of high-speed train and heavy duty transportation, the increasing load of traffic density, these are contributed to the destruction of track bolts, nuts bolts and then endanger the safety of the railway.

Bolt and nut connection is the most common way of fastening, which has a simple structure with features of easy accessibility, adjustment and so on. However, the factor of root stress concentration of ordinary triangular thread seriously affects the fastening strength. Therefore, reducing the root stress concentration and improving stress distribution is the main way to improve the fastening strength.

Generally there are three ways that can help achieve it. First, the fillet radius increase in thread root; Secondly, to increase the bolt threads trails and reduce the axial tensile stress of the bolts; Third, to change the structure of bolts and nuts, thereby change the local stress state of the bolts.

At home and abroad people usually use more high-strength bolts through the first or second method. However, due to limitation of thread form, the increase in the thread root radius and bolt thread trails, people cannot be arbitrarily changed. Because the third method means higher production costs, it is rarely used.

The maximum axial tensile stress of track bolt suffers mainly from nut surface. In this position if the nut part of the thread can be cut away to reduce the rigidity of the thread of the nut, this will change the contact stress distribution of the bolt and the nut. So the track bolt suffering can significantly reduce the maximum axial tensile stress and stress concentration, greatly improving the strength of the bolt. And changing the structure of the nut in the manufacturing process is not complicated, but the strength of the track bolt is greatly improved.

High strength of track bolt is mainly applied on bridge section and turnout (frog) section of the railway. In China, high strength bolt is made by high strength steel materials. The bolts, nuts and washers are made of high-strength steel, for example, 45 # steel, 40 # steel, 20 Manganese Titanium Alloy steel, 35CrMoA steel. But ordinary bolt is manufactured by Q235 steel.

Frog bolt

A frog bolt is connected the fishplate, they are mostly square head bolts. But they are usually with a variety of lengths and diameters that are depended on the rail section in use and the location of the bolt in the frog. Torque wrench is a railway tool that can be adjustable to meet the requirements of frog bolts. The hydraulic torque wrench is to tighten frog bolts and help keep frogs be in proper place.

Seen from the following table, we can figure out the specifications of common frog bolt in North America.

AGICO can manufacture two types of frog bolts that are used on frog or crossing. They are square head bolt and button head oval neck or elliptical neck bolt. All the bolts are made as full body bolts with cut threads in grades 5 and 8 of AREA specifications.

Now AGICO can manufacture all kinds of standards of track bolts, including Australia bolt, Russian bolt, American bolt, German bolt, etc. In addition, we can manufacture the required bolt as the client’s needs and drawings.

AGICO is a professional leader of railway fasteners manufacturer. Our products include rail clip, track bolt, track spike, fish plate, rail accessories with good quality and reasonable price. Our mission is to support you to expend your railway business.

Get in touch now

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!